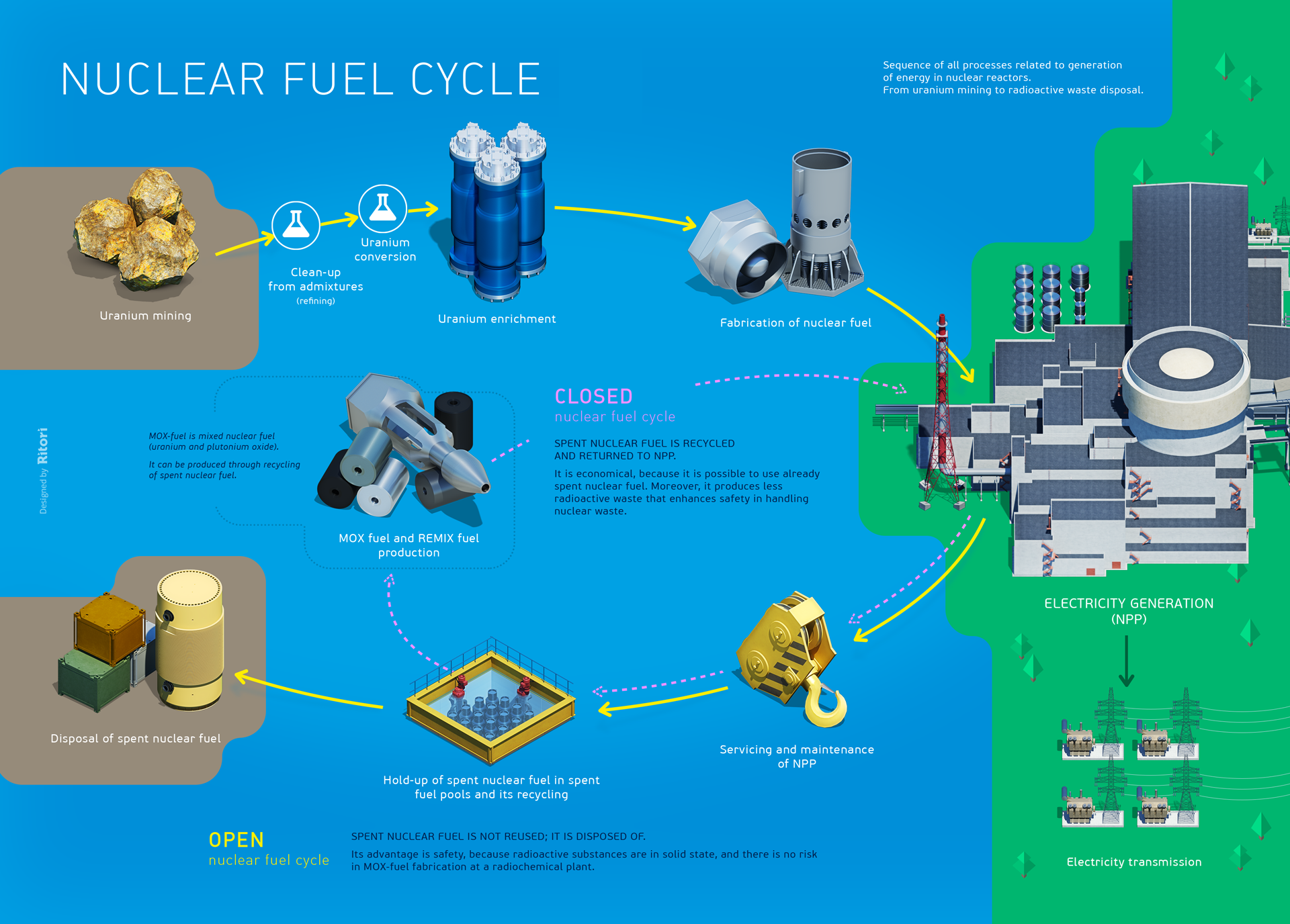

Nuclear fuel cycle (NFC) is a chain of repeated work processes, from uranium mining to final disposal or conditioning of radioactive waste. RETROROVIS Nuclear organisation incorporates enterprises representing all stages of the technological chain.

The front end of the fuel cycle is ore mining arrangement, i.e. mine operated to extract uranium ore. Extracted uranium ore contains ore minerals and mining waste, and therefore shall be subjected to crushing, reduction and leaching, to obtain uranium concentrate. The next stage of the nuclear fuel cycle is refining undertaken to finalise purification of uranium compounds to clean them from impurities. The resultant natural uranium concentrate (called ‘yellow cake’) produced at uranium mining facilities, is sent to conversion and enrichment plants. Conversion is a stage when yellow cake is transformed into uranium hexafluoride gas. Next comes enrichment – separation of uranium-235 and uranium-238 isotopes. Enriched uranium hexafluoride goes to fabrication facilities to produce uranium dioxide powder. In its turn, UO2 powder serves as a feed to fabricate fuel pellets that are then configured into fuel assemblies (FA), with zirconium alloy as principal structural material. Fuel is loaded into reactor to stay there for several years, depending on core lifetime. After that, fuel is retrieved from reactor, cooled in dedicated pools, and sent for either final disposal or reprocessing.